Preventing Warping and Cracking in Plastic Sheets: Practical Tips for DIY and Trade

Warped or cracked plastic sheets can wreck your project before it even starts. Whether you’re working with acrylic, polycarbonate, or PVC, knowing how to prevent plastic warping and cracking saves time and money. We’ll share practical tips that help your materials stay strong and true, plus explain why choosing cut-to-size plastic from Plastic Online sets you up for success every time. Learn more about how to prevent warping in extruded products here.

Understanding Plastic Warping and Cracking

If you’ve ever faced the frustration of dealing with warped or cracked plastic sheets, you’re not alone. Many factors play into these issues. Let’s explore what causes them so you can stop problems before they start.

Causes of Plastic Warping

Warping occurs when plastic sheets bend or twist out of shape. This often happens due to uneven heating or cooling. For instance, if one side of a plastic sheet heats up faster than the other, it can lead to warping. Imagine leaving a polycarbonate sheet under direct sunlight—this can cause one side to expand more than the other, leading to an unwanted curve.

Moreover, improper storage is a common culprit. Stacking heavy items on plastic sheets can apply uneven pressure, causing them to warp over time. By storing sheets flat and avoiding exposure to heat, you prevent plastic warping from becoming an issue.

Factors Leading to Plastic Cracking

Cracking is another concern, often resulting from applying too much force or incorrect handling. If you’re drilling into plastic, using a standard drill bit can cause cracks. Instead, a bit designed for plastics helps maintain the integrity of your sheet. Countersinking plastic is a technique to watch out for, as incorrect angles can lead to splits.

Temperature also plays a role here. Rapid cooling or heating can make plastic brittle. For example, if you take an acrylic sheet from a hot environment to a cold one quickly, cracks may form. By controlling the environment, you keep your sheets intact.

Thermal Expansion in Plastics

Did you know plastic expands and contracts with temperature changes? Thermal expansion in plastics can lead to warping and cracking. When plastics expand, they need space to move. Without proper installation gaps, sheets can buckle or crack. Consider a PVC sheet installed without enough room to expand; it might buckle under the pressure.

Understanding these causes helps you make better choices for your projects. Next, we’ll cover actionable steps to prevent damage.

Practical Tips to Prevent Damage

Now that you know the causes, let’s dive into practical steps to prevent warping and cracking. These methods ensure your plastic sheets remain in top condition.

Correct Sheet Fixing Methods

How you fix your sheets matters. Using the right method ensures stability and longevity. One effective way is to use a router cutting plastic for precision edges. This helps in creating clean cuts that don’t stress the plastic.

Avoid fixing plastic sheets too tightly. Allow a slight movement to accommodate expansion. By using flexible fixings, such as rubber washers, you reduce tension and keep your plastic from cracking.

Importance of Installation Gaps

Leaving room for expansion is crucial. Installation gaps allow plastic sheets to expand and contract without damage. For example, when installing an acrylic sheet (Perspex), ensure gaps between the edges and the frame.

By planning these gaps, you prevent stress buildup. This small step can save you from costly replacements and repairs.

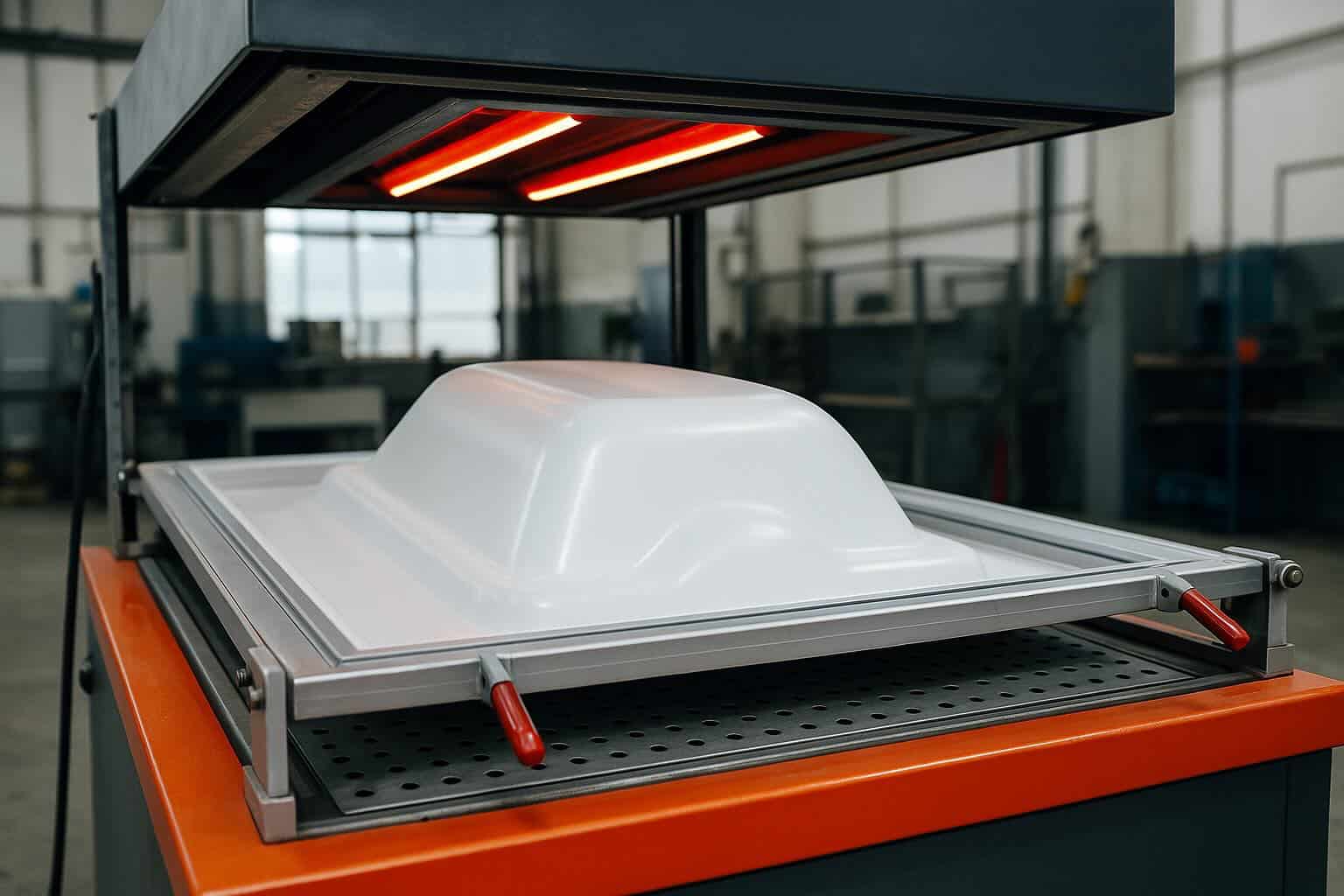

Annealing Acrylic for Stability

Annealing is a process that stabilises acrylic sheets, reducing internal stresses. The trick is to heat the acrylic gradually, then cool it slowly. This strengthens the material, making it less prone to warping or cracking.

If you’re working with large sheets, consider annealing them. The process may sound complex, but the benefits include longer-lasting materials and fewer surprises down the line.

Choosing the Right Plastic and Services

Picking the right plastic and services can make or break your project. Here’s why you should consider Plastic Online for reliable solutions.

Benefits of Cut-to-Size Plastic

Opting for cut-to-size plastic saves you both time and effort. With precision cutting, you get materials that fit your specific needs. This means less waste and fewer adjustments on your part.

Plus, when you order from Plastic Online, you ensure quality cuts every time. This approach supports DIY enthusiasts and professionals alike.

Custom Fabrication Services Overview

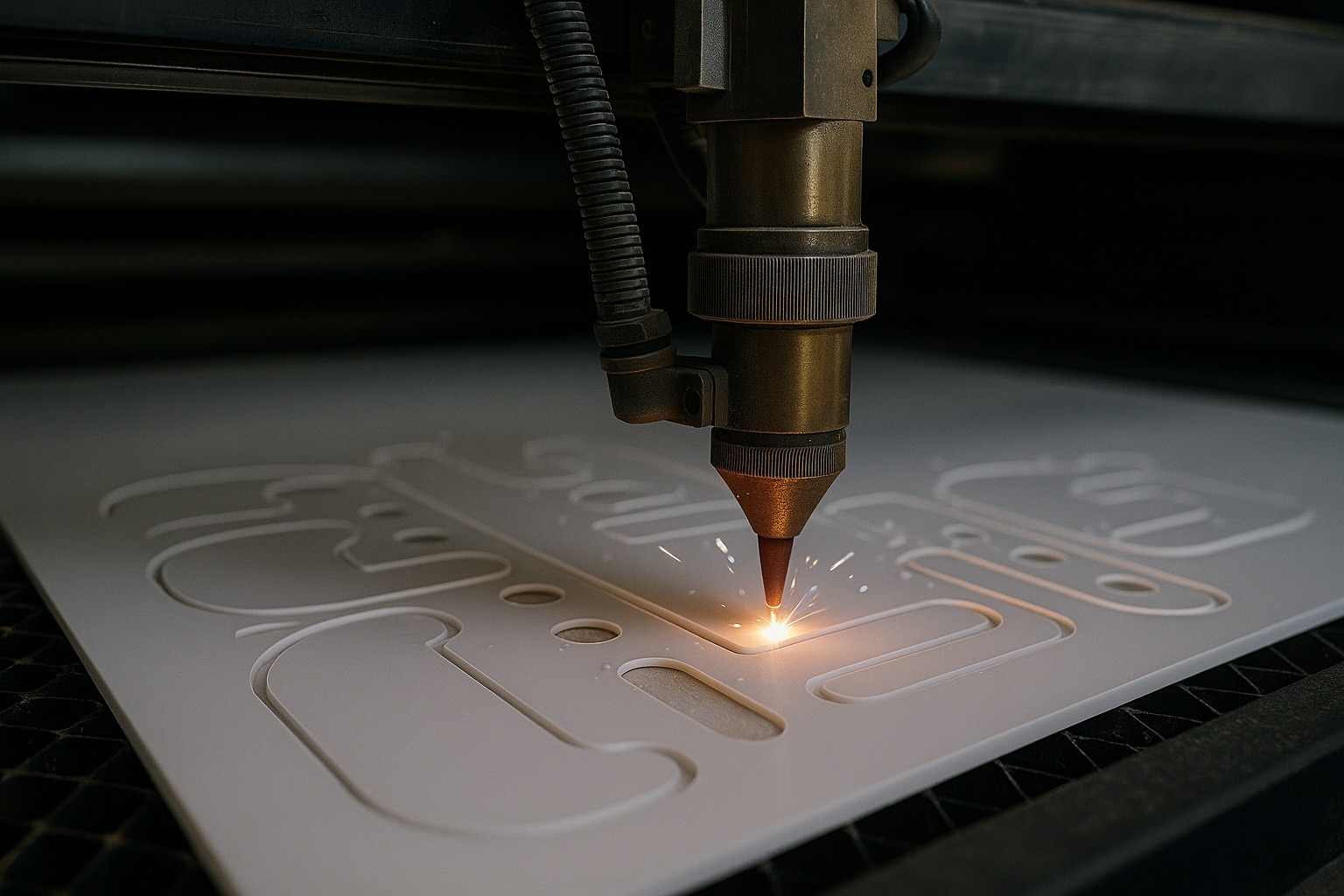

Our custom fabrication services cater to unique project requirements. Whether you need intricate designs or bulk orders, we’ve got you covered. Services like CNC laser cutting acrylic and water jet cutting plastics offer precision and flexibility.

These options provide the freedom to create without limits. By trusting expert services, you achieve professional results with ease.

Why Choose Plastic Sheets Australia

Choosing Plastic Sheets Australia means choosing quality and reliability. Our local production ensures quick turnarounds and consistent standards. Plus, our award-winning service offers peace of mind.

With a commitment to excellence, we’re here to support your projects from start to finish. Turn to us for all your plastic needs, and experience the difference.

In summary, preventing warping and cracking in plastic sheets is about understanding the causes and applying the right techniques. By choosing the right products and services, you set your projects up for success. Keep these insights handy, and watch your projects thrive.

Learn how to avoid costly mistakes with plastic materials