Pick the Right Plastic for the Job: A Practical Guide for Tradies and DIYers

Picking the right plastic can make or break your project. Choosing between acrylic sheet Australia and polycarbonate sheet Australia isn’t just about cost—it’s about strength, clarity, and durability under Aussie conditions. This guide breaks down key features like impact resistance, UV stability, and machinability, so you get plastic sheets cut to size that fit your exact needs. Let’s get you sorted with the right materials and services, whether you’re a tradie or tackling DIY plastic projects. For more insights, check out this guide to choosing the right plastic material for your project.

Choosing the Right Plastic

Choosing the right plastic can feel a bit daunting, but it starts with understanding what matters most—key properties, strength, and resistance features.

Key Properties to Consider

When picking plastic, think beyond just the basics. Clarity, strength, and weather resistance are crucial. If your project is outside, make sure the plastic can handle the sun’s rays. UV resistant plastic is your go-to here. For projects in the kitchen, consider using a food-safe plastic sheet. It’s all about matching the material to your needs. Looking for plastics that can withstand chemicals? Polypropylene sheet chemical resistant might be the answer. This careful selection ensures your project is durable and fit for purpose.

Understanding Material Strength

Strength is a big deal when it comes to plastics. You want materials that can stand up to challenges without breaking a sweat. Impact resistant plastic sheet options are perfect for tough environments. It’s not just about holding up under pressure but doing so while maintaining form and function. Whether you’re building a machine guard or a shed window, knowing the material’s load capacity means your structure remains intact. For further guidance on selecting the right strength, check out this CNC plastics selection guide.

UV and Impact Resistance

Aussie sun can be harsh. If your project sees the sun often, UV resistance is a must. Polycarbonate sheet Australia is often favoured due to its ability to resist UV rays while maintaining clarity. When it comes to impact, some plastics can take a hit without cracking. This is essential for items like skylights or protective covers. Opt for materials that balance light transmission with durability, and you’re set for success.

Applications for Tradies and DIYers

Once you understand which plastics to use, it’s time to apply this knowledge to real-world projects. Whether you’re a seasoned tradie or a weekend DIYer, knowing what works where is crucial.

Common Projects and Needs

Tradies and DIYers often tackle a wide range of projects. From home renovation to outdoor signage, the right plastic makes all the difference. Acrylic sheets are excellent for decorative features due to their high clarity. Meanwhile, HDPE sheet supplier options might be better for water-resistant applications. Understanding these nuances ensures your project not only looks good but performs well, too.

Comparing Acrylic vs Polycarbonate

Choosing between acrylic and polycarbonate can be tricky. Acrylic vs polycarbonate decisions often come down to budget and usage. Acrylic offers clarity and is generally cheaper, making it great for display cases. Polycarbonate, however, is tougher, ideal for security glazing. It’s about understanding what each offers and matching it to your project’s needs. Explore plastic material selection tips for deeper insights.

Specialised Fabrication Services

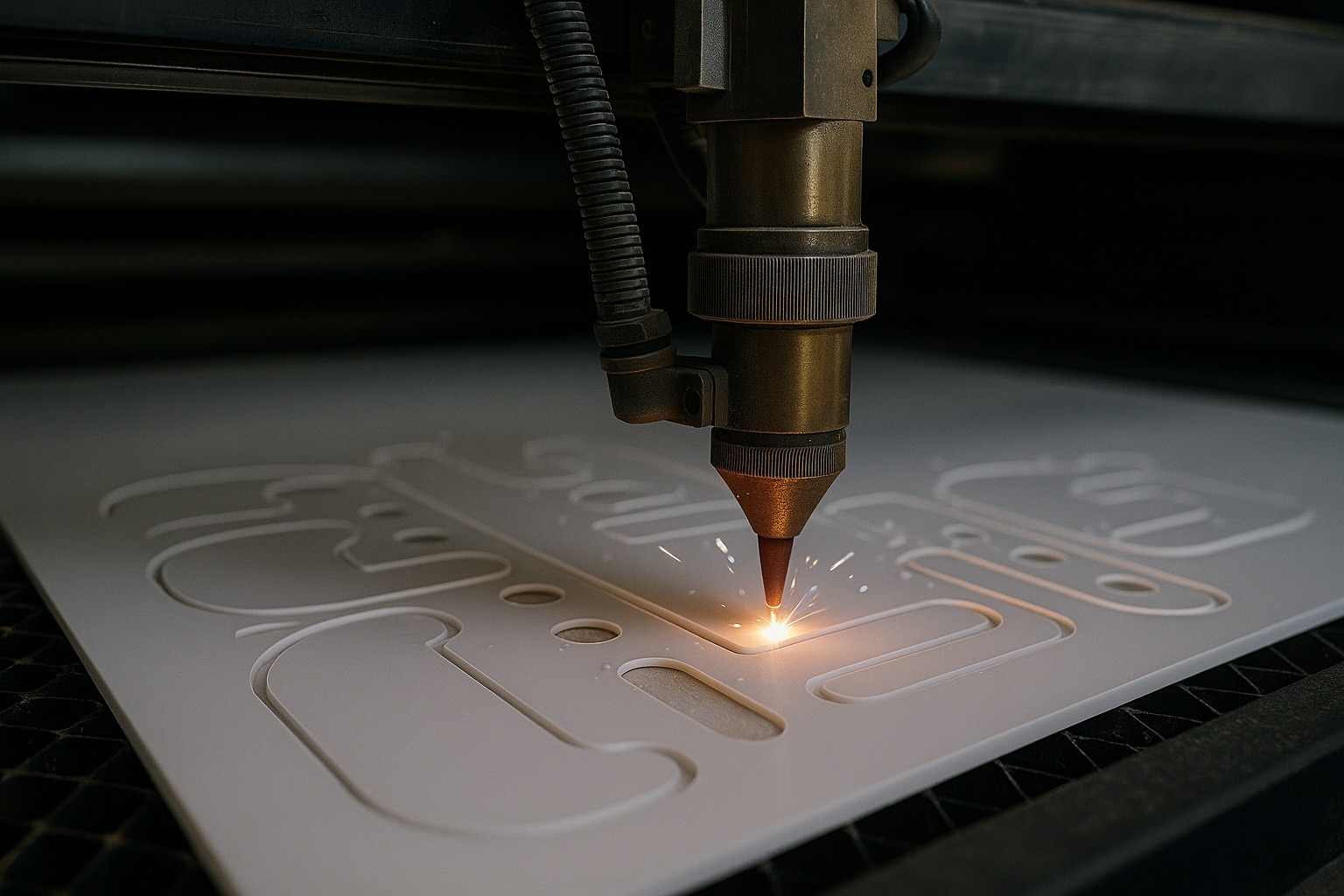

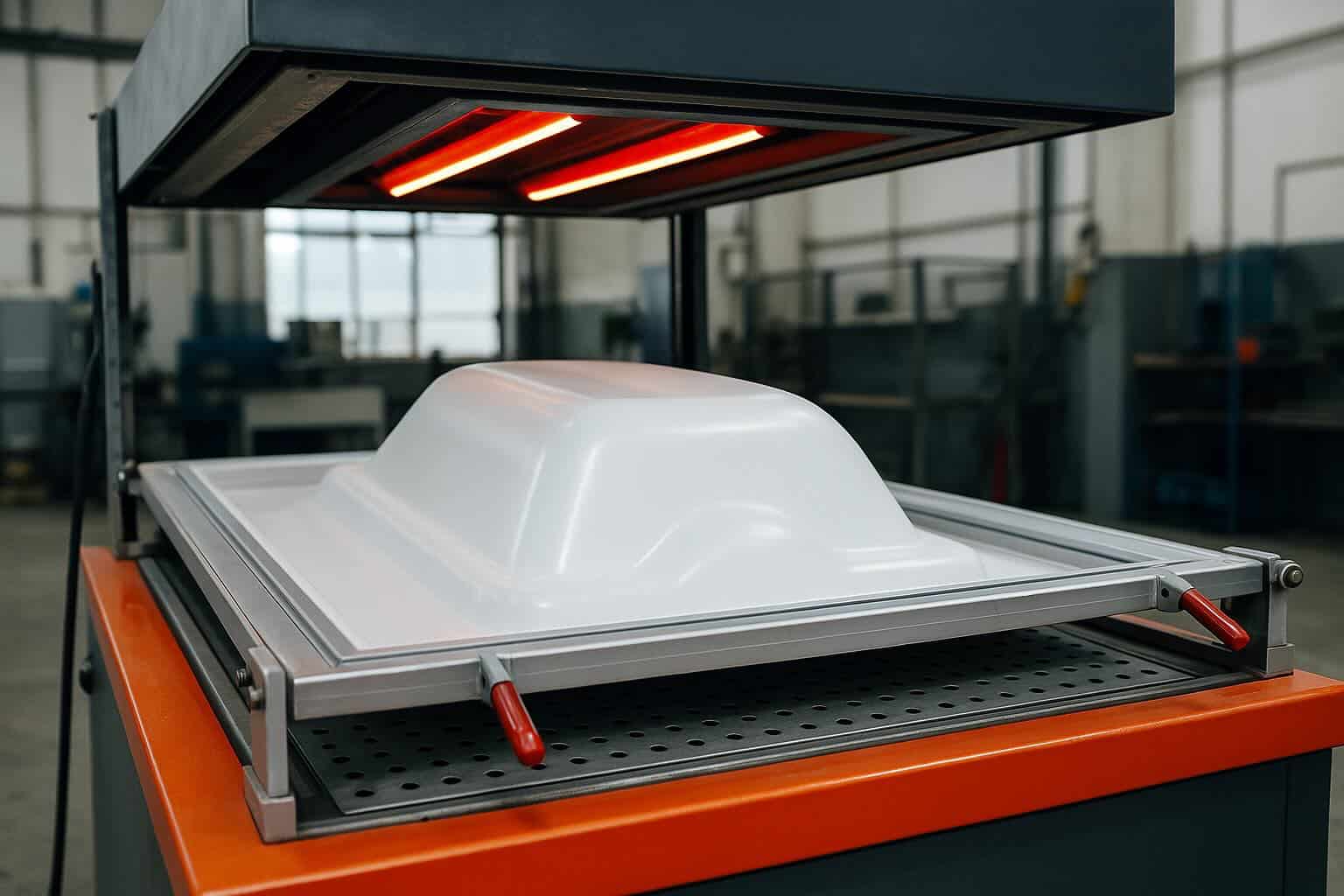

Sometimes off-the-shelf just won’t cut it. For unique projects, specialised fabrication services are the answer. Whether it’s custom signs or intricate designs, having a partner who can deliver precise, customised solutions is invaluable. Services like CNC laser cutting plastics or vacuum forming services allow for creativity without compromising on quality. With the right support, even complex projects become manageable.

Ordering and Customisation

Knowing what you need is just the start. The next step is getting those materials in the right size and shape, ready to go.

Plastic Sheets Cut to Size

Why struggle with large, unwieldy sheets? Getting plastic sheets cut to size saves time and hassle. It’s about precision and fit, ensuring each piece slots perfectly into your project. Whether you’re creating a window or crafting a unique display, custom sizing is a game-changer. Check out this comprehensive guide to buying plastic sheets for more details.

CNC and Vacuum Forming Services

Precision is key, and CNC and vacuum forming services provide just that. They allow for complex cuts and shapes with minimal waste. CNC routing plastics can handle intricate designs, while vacuum forming is perfect for volumetric shapes. From bespoke signage to protective covers, these services elevate your project to professional standards.

Local Manufacturing and Delivery Options

Supporting local not only boosts the economy but also ensures faster delivery and better quality control. Local manufacturing means you can get what you need without long waits. Plus, it’s easier to communicate specific requirements, ensuring what you get is exactly what you envisioned. For more on how to ensure quality and timely delivery, consult this plastic material selection guide.

Now that you’re armed with the knowledge to choose and customise your plastics, you’re ready to take on any project with confidence. Remember, the right material selection can transform your work, providing both beauty and functionality.

Learn how to avoid costly mistakes with plastic materials