Top Fabrication Challenges for Tradies and DIY Enthusiasts — and How Plastics Solve Them

Fabrication can slow you down when materials don’t fit or break under pressure. Tradies and DIYers face tight deadlines and tricky designs that demand the right plastics to get the job done right. With Plastic Online’s cut-to-size plastic and expert fabrication services, you’ll find durable, precise materials tailored for your project. Let’s break down common challenges and show how the right plastic choices keep your work smooth and reliable. For more insights, check out this link.

Common Fabrication Roadblocks

When you’re in the middle of a project, the last thing you want is a setback. Let’s explore some hurdles you might face and how to overcome them.

Precision Cutting Challenges

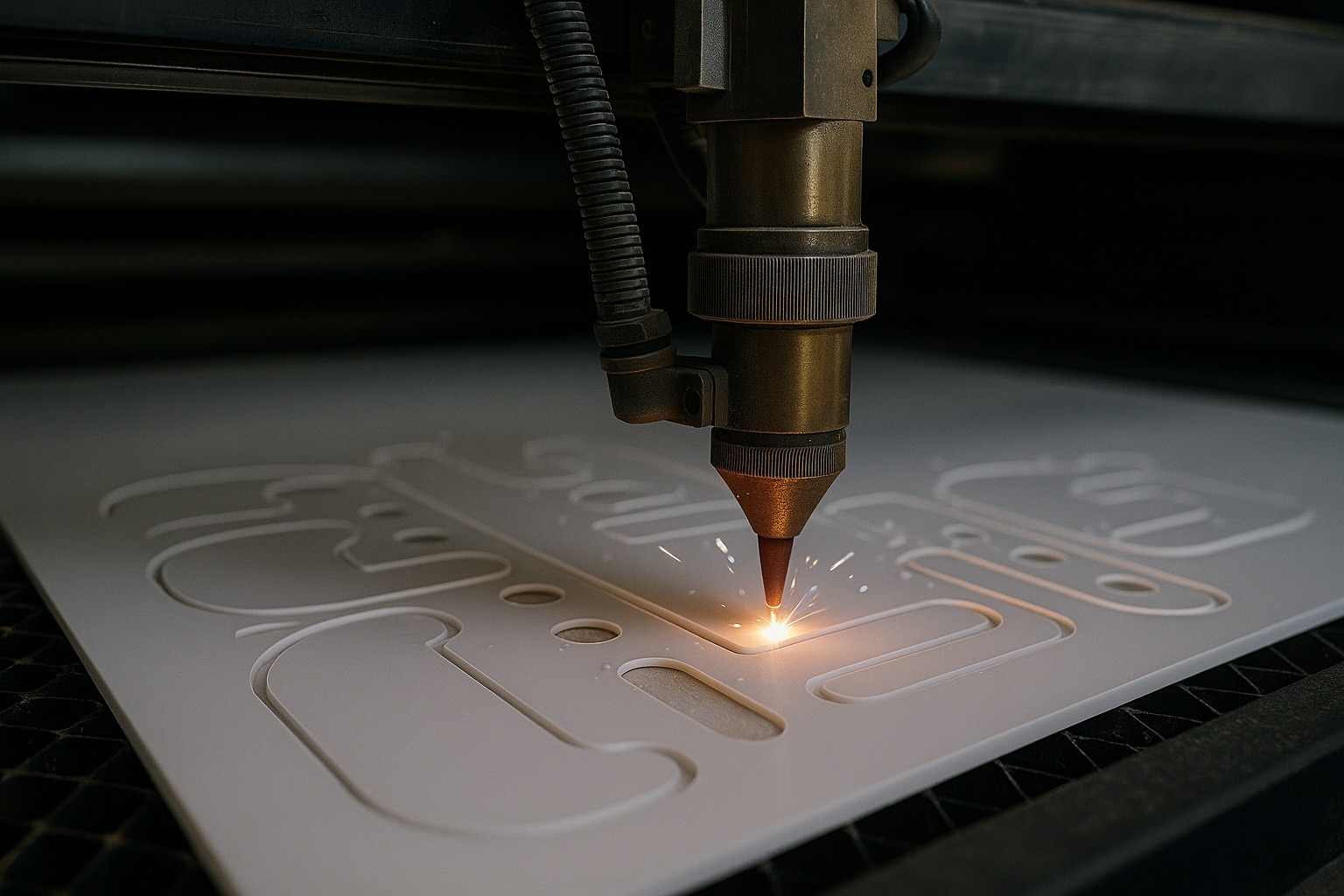

Getting the exact dimensions is crucial for any project. You can’t afford errors here. Even a small miscalculation can lead to wasted materials and time. One common issue is relying on manual cutting methods, which often lack the accuracy needed. Instead, consider using CNC laser or water jet cutting. These technologies can achieve remarkable precision, ensuring that each cut matches your specifications exactly. This means fewer errors and more time saved on your projects. Dive deeper into precision cutting challenges here.

Material Durability Concerns

Materials that don’t last can be a real pain. Imagine finishing a project only to find it breaking down soon after. This often happens when the wrong type of plastic is chosen. For example, acrylic might not be the best for outdoor projects due to UV exposure. Polycarbonate, on the other hand, offers better durability and resistance. By selecting the right material from the start, you can ensure your project stands the test of time. Learn more about durability issues in fabrication here.

Meeting Project Deadlines

Deadlines can be stressful, especially when delays arise. The root cause often involves waiting for materials or dealing with supply chain hiccups. By sourcing your plastics locally from a trusted supplier, you can cut down on wait times significantly. Plastic Online offers quick delivery on cut-to-size plastics, helping you stay on schedule and avoid unnecessary stress.

Plastic Solutions for Tradies

Now that we’ve looked at the challenges, let’s see how plastics come to the rescue, offering practical solutions for common issues.

Benefits of Cut-to-Size Plastics

Why settle for one-size-fits-all when you can have custom precision? Cut-to-size plastics mean no more wrestling with oversized sheets or struggling to make ill-fitting pieces work. You get exactly what you need, reducing waste and saving money. Plus, when you order cut-to-size, it arrives ready to use, speeding up your workflow.

Understanding CNC Laser and Water Jet Cutting

These cutting methods might sound high-tech, but they make your life easier. A CNC laser uses a focused beam to cut materials with incredible accuracy, perfect for intricate designs. Meanwhile, water jet cutting employs high-pressure water mixed with abrasives, suitable for thicker plastics. Both methods minimize material waste, making them environmentally friendly choices for modern fabrication. Explore more about these techniques here.

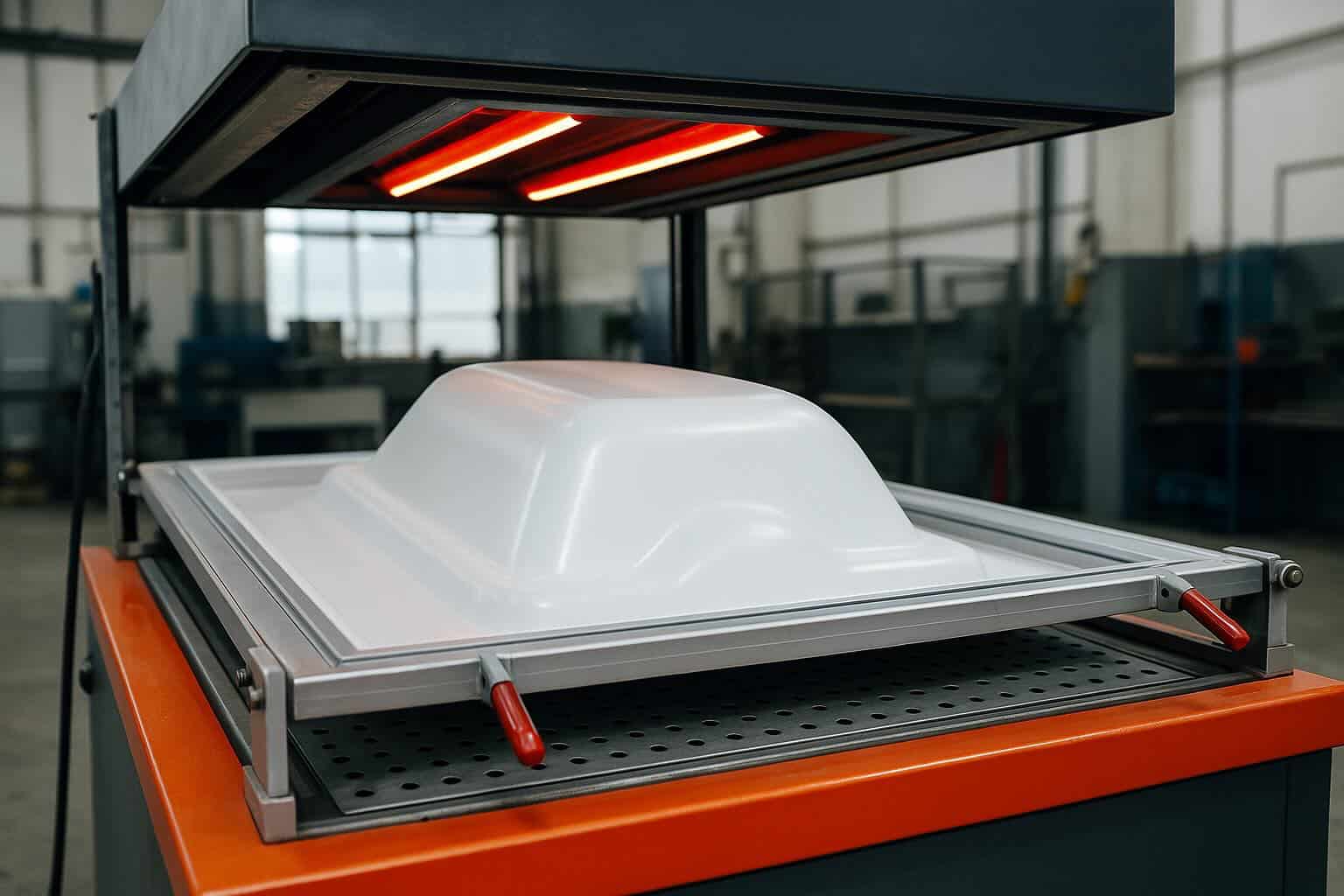

Thermoforming and Vacuum Forming Techniques

Creating complex shapes? Thermoforming and vacuum forming are your go-to processes. They involve heating plastic sheets and forming them over molds. This is ideal for producing items like custom signage or automotive parts. The result? A seamless, professional finish that meets your exact specifications.

Selecting the Right Plastic Material

Choosing the right material can be a game-changer. It affects durability, appearance, and longevity. Here’s how to make the best choice.

Choosing Between Acrylic and Polycarbonate

Acrylic is clear and attractive, often used in displays and signage. It’s lighter than glass and offers good impact resistance. Polycarbonate, however, is tougher, making it suitable for safety applications. Need something that can withstand high impact? Polycarbonate is the way to go. It’s all about matching the material to your project’s needs.

Applications for Food Grade and Marine Plastic

In environments that demand hygiene, food-grade plastics like HDPE are essential. They ensure safety and compliance with health standards. Marine plastics, on the other hand, are designed to resist saltwater corrosion. This makes them perfect for boats or seaside constructions. Choosing the right type helps ensure project success in specific conditions.

UV and Impact Resistant Options

Exposure to sunlight can degrade certain plastics. That’s where UV-resistant materials come in. They maintain their strength and color, even when exposed to harsh sunlight for long periods. For applications that require toughness, look for impact-resistant options. These materials can withstand heavy use without cracking or breaking.

Your project deserves the best materials and techniques. By understanding these options, you ensure a smoother, more successful fabrication process.

Learn how to avoid costly mistakes with plastic materials