The hidden costs of ignoring fabrication accuracy in plastic products

Ignoring plastic fabrication accuracy costs more than you think. Poor dimensional precision leads to rework, wasted materials, and project delays that hit your budget and timeline hard. In this post, you’ll learn how clear fabrication tolerances and precision plastic cutting save you money and headaches—and why Plastic Online’s local, Australian-made plastics and expert services are your best bet for a job done right the first time. For further insights into the impact of plastic use and its costs, you might find this article interesting.

The True Cost of Poor Accuracy

Overlooking the importance of accuracy in plastic fabrication leads to several hidden costs. Let’s delve into the specifics and see how these costs can affect your projects.

Rework and Waste in Plastic Fabrication

Mistakes in fabrication lead to rework, which is both time-consuming and costly. Imagine crafting a batch of 100 plastic components, only to realise later they don’t meet the required specifications. Now, you’re forced to redo the work, wasting time and materials. With precision plastic cutting, such issues are minimised. High accuracy ensures components fit perfectly the first time. When you cut corners, you risk incurring extra costs from wasted materials and additional labour. By prioritising accuracy, you not only save money but also prevent unnecessary waste. This article on modern fabrication costs further explains how precision can lead to cost savings.

Delays and Warranty Issues

Project delays are more than just an inconvenience; they can affect your bottom line. Inaccurate plastic parts can cause bottlenecks in your production line. If parts don’t fit as expected, projects stall while you wait for replacements. This not only affects delivery timelines but can also lead to warranty claims if products don’t perform as intended. Addressing these issues upfront by ensuring precise fabrication can save your company from potential legal and financial problems down the line.

Safety Risks in Ignoring Tolerances

Safety shouldn’t be compromised by ignoring tolerances. Poor accuracy can lead to weak components, which may not withstand stress. In critical applications, such as safety barriers or protective gear, even a small error can have serious consequences. By focusing on precision, you ensure every component can perform safely and reliably. This approach not only protects end-users but also safeguards your reputation as a reliable supplier.

Smart Solutions for Precision

With the risks clear, how do you ensure precision? By adopting smart solutions that align with your project needs, you can avoid these pitfalls.

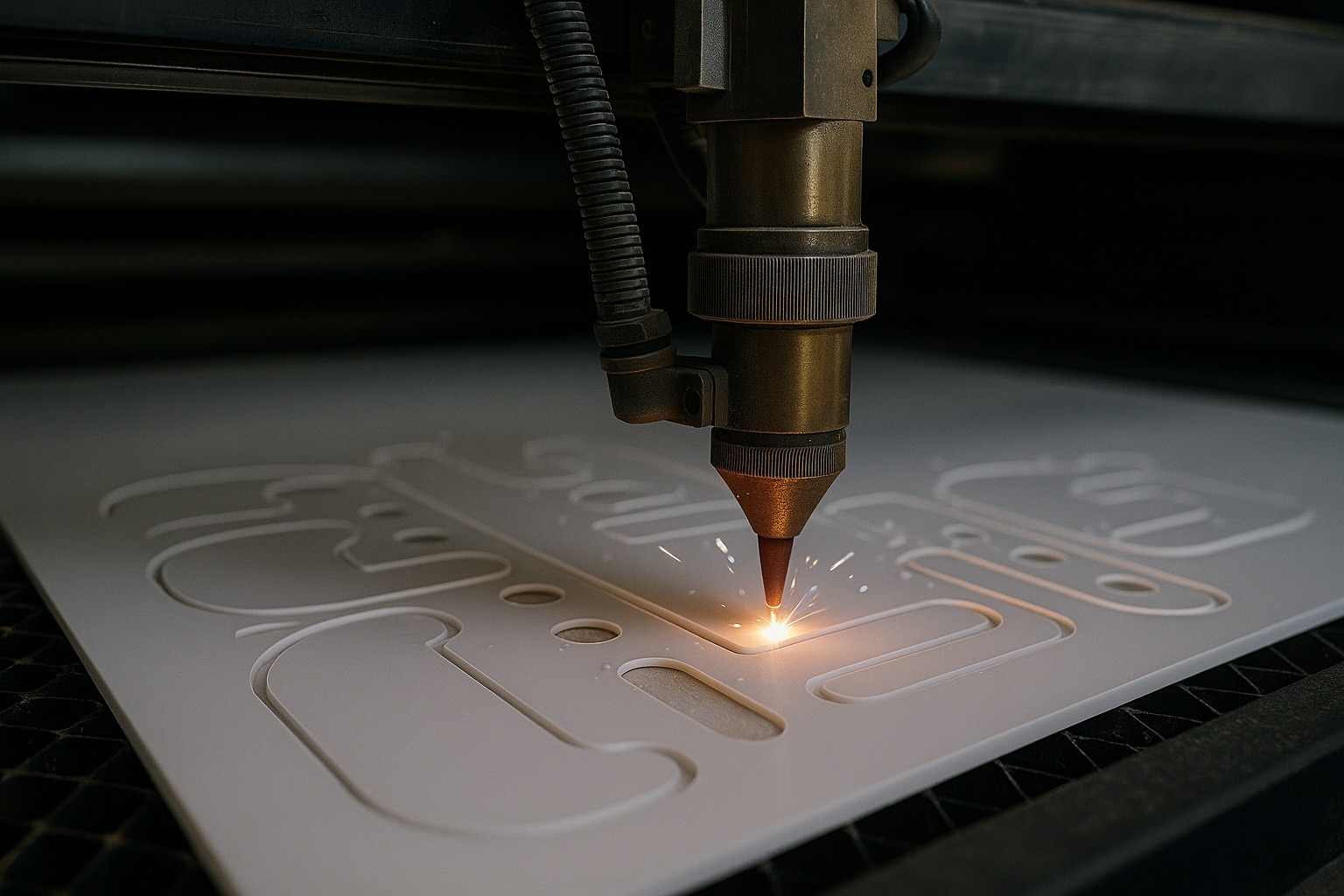

Benefits of CNC Cutting in Australia

CNC cutting provides unmatched precision for plastic fabrication. With this technology, each cut is consistently accurate, reducing the chances of errors. CNC cutting allows for complex designs without sacrificing quality. Plus, by using Australian-based services, you benefit from faster turnaround times and local expertise. This ensures your project stays on schedule and meets all specifications.

Value of Clear Tolerance Specs

Clear tolerance specifications are vital for any fabrication process. They serve as a blueprint, guiding every cut and adjustment. By setting precise tolerances, you minimise the guesswork in fabrication. This clarity ensures that each component fits perfectly, facilitating smooth assembly and reducing the need for rework. Remember, clear specs are a cost-effective strategy in the long run.

Early Engagement with Plastic Online

Engaging with experts like Plastic Online early in your project ensures a seamless process. By collaborating from the start, you benefit from expert advice on material selection and design considerations. This proactive approach helps in identifying potential issues before they become costly problems. With Plastic Online, you gain access to a team dedicated to delivering precision plastic solutions tailored to your needs.

Choosing the Right Plastic Service

Selecting the right plastic service provider is crucial for project success. Here’s why your choice matters.

Why Local Manufacturing Matters

Local manufacturing offers several advantages over international suppliers. By choosing Australian-made plastics, you ensure consistent quality and quick delivery. Local expertise means you can rely on support when needed. Plus, by supporting local businesses, you’re contributing to the community and economy. Local production aligns with sustainable practices, reducing the carbon footprint associated with long-distance shipping.

How to Ensure a No-Fuss Fit

Ensuring a no-fuss fit starts with precise measurements and clear communication. Work closely with your supplier to convey your requirements accurately. Use tools like CAD designs to visualise the final product and confirm specifications. By taking these steps, you minimise the risk of mismatched components and ensure smooth assembly.

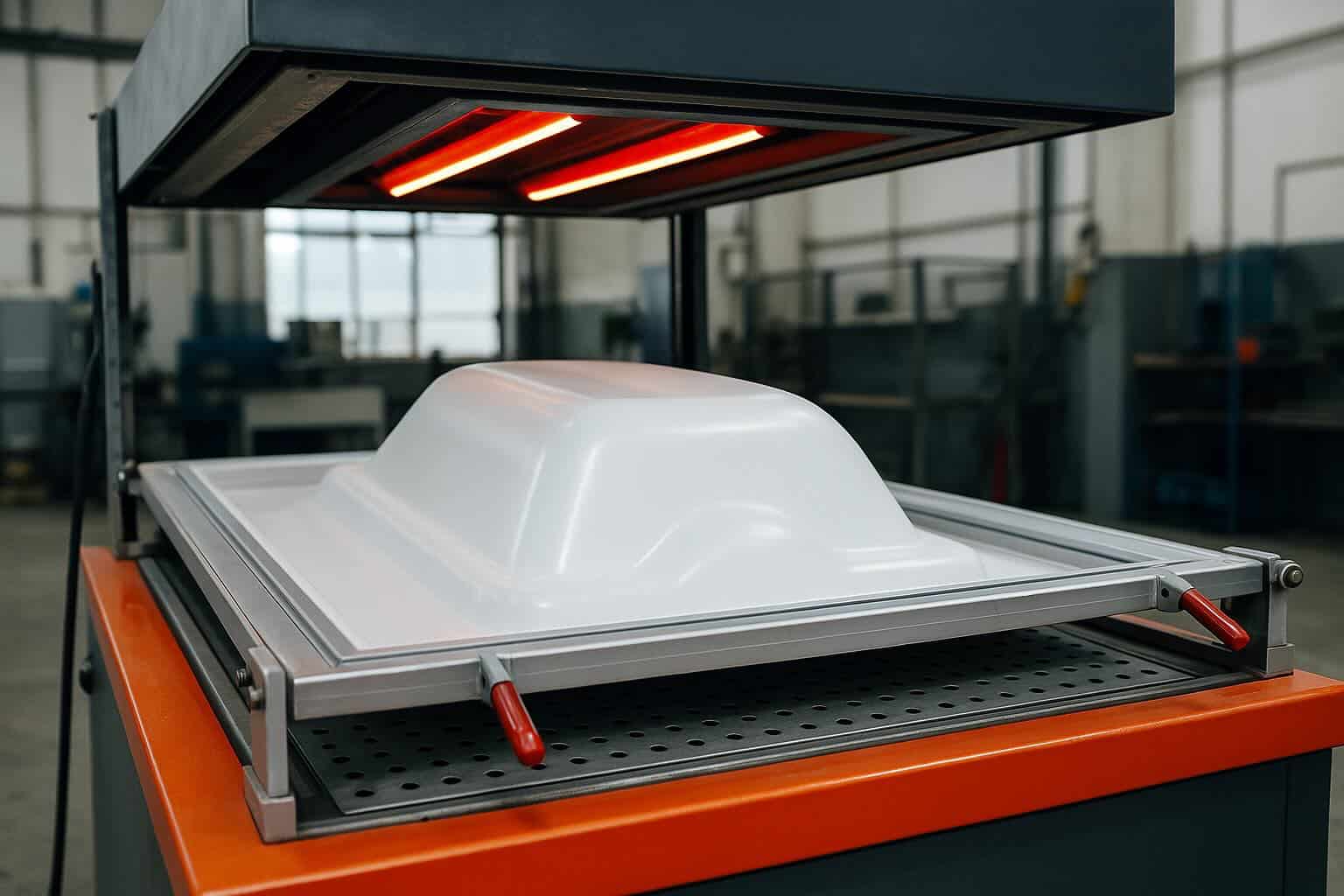

Plastic Online’s Custom Fabrication Services

Plastic Online offers comprehensive custom fabrication services to meet diverse needs. From cut-to-size plastic sheets to intricate CNC cutting, we provide solutions that cater to both DIY and professional projects. Our local manufacturing facilities ensure quick turnaround and reliable service. Partner with us for your plastic needs and experience the benefits of precision and quality. Explore our range of services to find the perfect solution for your next project.

Protect your projects by choosing quality plastics and precise cuts