Cheap plastics cost more: how poor quality undermines durability and safety

Cheap plastics might seem like a bargain, but they often hide costly problems. When your project depends on materials that crack, warp, or fail under impact, it’s not just frustrating—it puts safety on the line. Choosing an Australian plastic supplier you can trust means getting cut-to-size plastic sheets and fabrication services that stand up to the test. Keep reading to learn how poor-quality plastics can derail your work and why certified, precision-cut materials make all the difference. For more insights, visit this report.

Risks of Low-Grade Plastics

When you choose low-grade plastics, you’re opening the door to a host of potential problems. Let’s dive into the specific risks that come with cutting corners on quality.

Premature UV Cracking

Cheap plastics often lack proper UV protection, leading to rapid degradation when exposed to sunlight. Imagine you’re working on a project that requires outdoor durability. If your materials start cracking after just a few months, it can cause significant setbacks and additional expenses. UV-stabilised plastics are crucial for longevity. They resist the sun’s harsh rays, ensuring your projects stay intact. Without this stability, repairs or replacements become a costly necessity.

Brittle Impact Failures

Think your plastic won’t break under pressure? Low-quality options might. They tend to become brittle and shatter under unexpected impacts. For example, if you’re using plastic in a construction setting, a simple fall or knock can lead to disaster. This is particularly concerning for safety shields or machine guards, where integrity is non-negotiable. Polycarbonate sheet impact resistance is vital here, offering toughness that ensures safety and reliability. Choose wisely to prevent mishaps and maintain a safe environment.

Chemical Attack Concerns

Not all plastics can withstand exposure to chemicals. Low-grade materials often fail when faced with substances like cleaners or industrial solvents. If you’re in an environment where chemical exposure is commonplace, opting for chemical-resistant PVC can save you headaches. Consider a food processing facility where hygiene is paramount. Using subpar materials could lead to contamination risks or material failure. Protecting your operations starts with choosing the right plastic for the job.

Choosing Quality Plastics

Understanding the risks of low-grade plastics is crucial. But how do you ensure you’re making the right choice? Here’s where selecting quality materials comes into play.

Certified Materials Benefits

Investing in certified materials means peace of mind. These plastics have been rigorously tested to meet industry standards. Why does this matter? Certified plastics ensure consistent quality, crucial for projects demanding precision. For instance, food-grade HDPE is certified for safety, making it suitable for food-contact applications. With certification, you’re not just buying a product; you’re investing in reliability and performance.

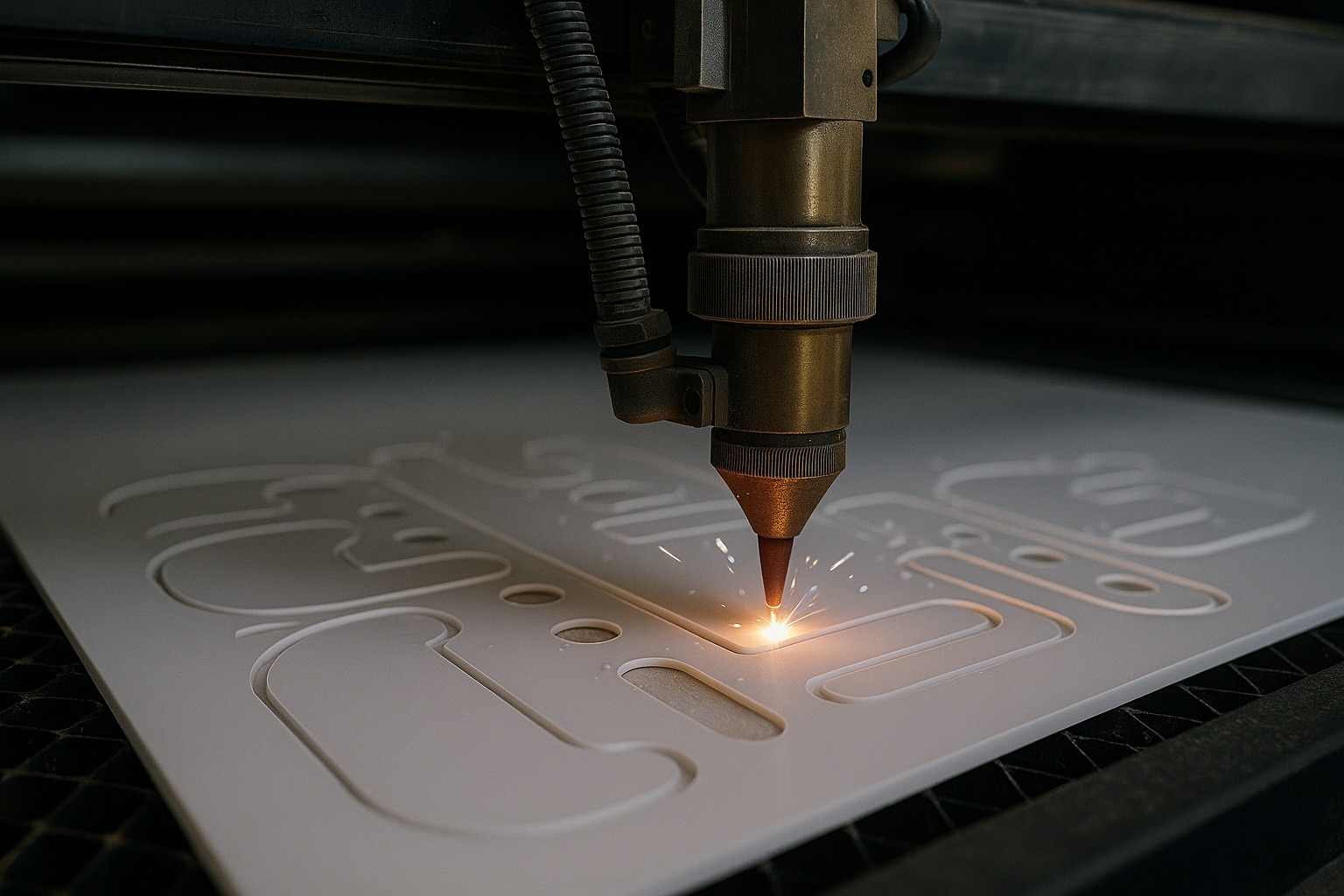

Precision Fabrication Advantages

Quality isn’t just about the material, it’s also about the cut. Precision fabrication ensures your plastics fit perfectly, every time. Imagine needing specific dimensions for a machine part. With precision CNC laser cutting plastics, you achieve tight tolerances that guarantee functionality. This level of accuracy reduces waste, saves time, and enhances project outcomes. Precision is more than a benefit, it’s a necessity for successful execution.

Importance of AS/NZS Compliance

Compliance with standards like AS/NZS is imperative for ensuring safety and quality. These standards dictate the minimum requirements for products used in various applications. Why gamble with non-compliant materials when your reputation could be at stake? AS/NZS compliant materials offer proven performance and safety assurance. They’re your best bet against costly failures and ensure alignment with legal and safety expectations.

Plastic Online Services

At Plastic Online, we provide a wide range of services designed to meet your specific needs. Here’s how we can support your projects with high-quality solutions.

Cut-to-Size Plastic Sheets

Our cut-to-size service takes the hassle out of your projects. Whether you’re a DIY enthusiast or a trade professional, getting the exact dimensions you need makes all the difference. We use advanced cutting technologies to deliver precise results. This means no more time wasted on adjustments. With quick turnaround plastics, you can keep your project on schedule and within budget.

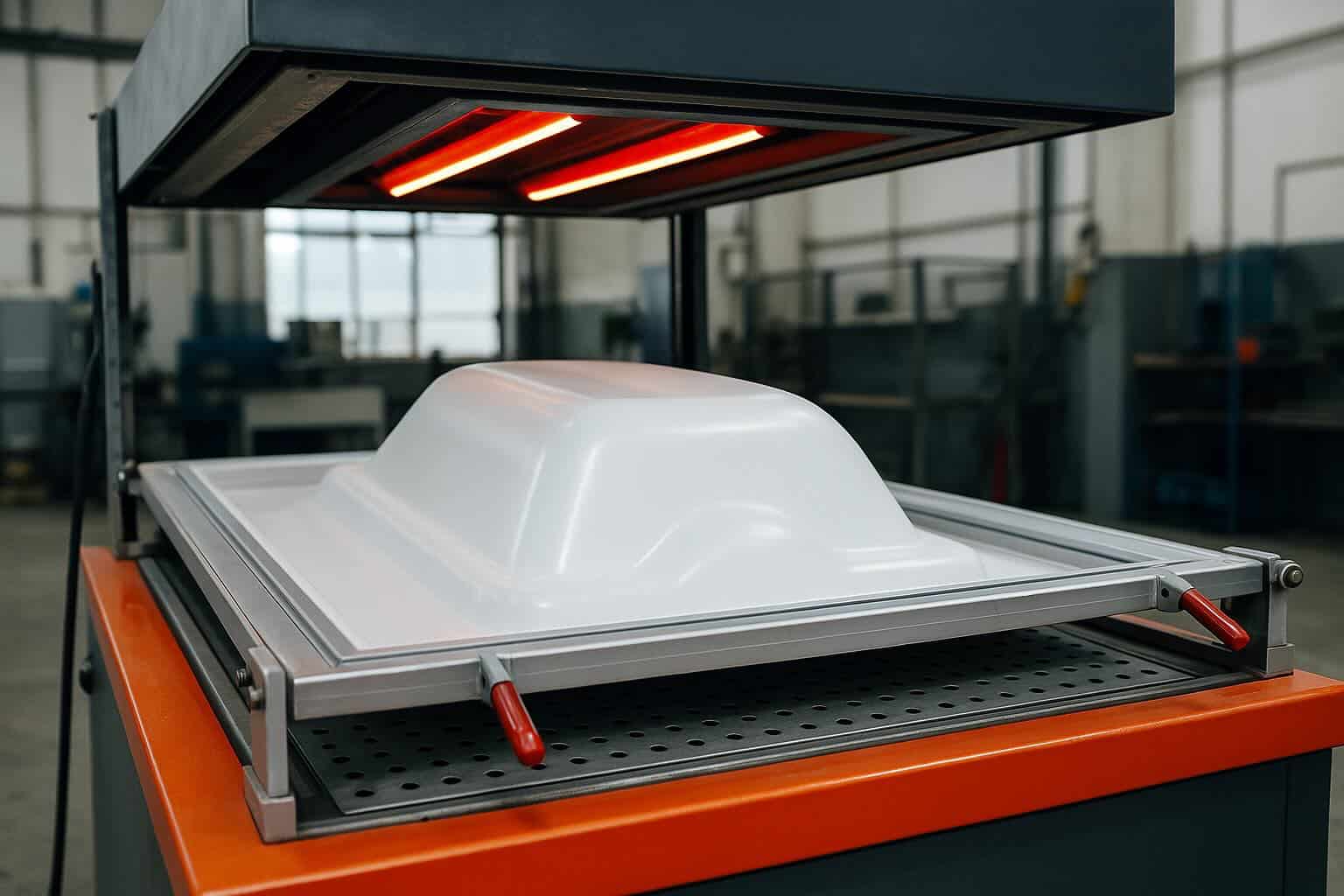

Custom Plastic Parts Fabrication

Looking for something unique? Our custom plastic parts fabrication service is here to help. From design to manufacture, we handle it all. This service is ideal for those with specific requirements that off-the-shelf products can’t meet. Our team’s expertise ensures that your custom parts are not only high-quality but also perfectly tailored to your project’s needs.

Quick Turnaround and Delivery

In today’s fast-paced world, waiting weeks for materials isn’t always an option. That’s why we pride ourselves on quick turnaround and reliable delivery. Our local manufacturing Australia-based operations mean you receive your products faster, without compromising on quality. The longer you wait, the more opportunities slip away. Let us help you stay ahead with timely service that supports your ambitions.

In conclusion, choosing the right plastic materials and services can make or break your project. By understanding the risks of low-grade plastics and opting for quality, certified options, you ensure durability and safety. At Plastic Online, we’re committed to providing top-notch solutions that meet your needs efficiently and reliably. Trust us for your next project and experience the difference quality makes.

Protect your projects by choosing quality plastics and precise cuts