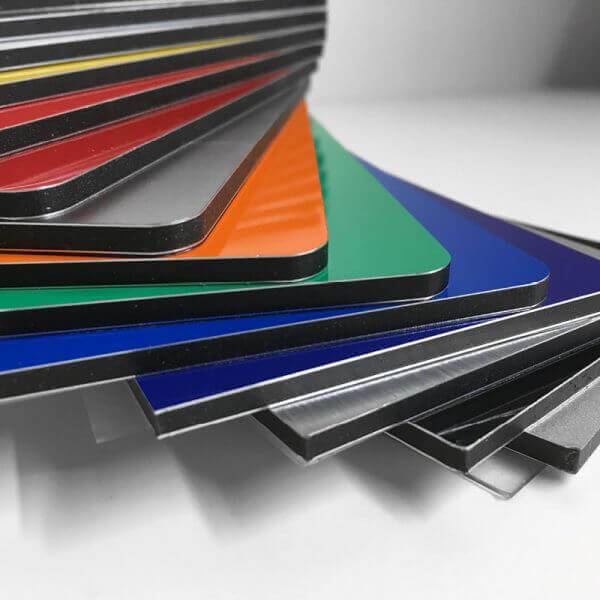

Aluminium Composite Material (ACM) Sheet

CM (also called ACP) combines two thin aluminium skins with a bonded core to produce a sheet that’s strong, flat and easy to fabricate. It’s the industry standard for retail and shop signage, reception panels, wayfinding, exhibition displays and light cladding. Our panels are available in 3 mm, 4 mm and 6 mm with white, black and colour finishes, plus brushed metallic effects. Panels machine well on CNC routers, cut cleanly on saws, accept V‑groove folding, and fix with rivets, screws, or high‑bond tapes and adhesives. We can cut to size, round corners, drill, countersink and add slots for mounting—perfect for fast project turnaround.

Compliance note: PE‑core “signage grade” is not intended for high‑rise façade use. FR‑core options are available on request where specified.

Highlights (bullets):

- Flat, smooth face for premium graphics

- Reliable outdoor performance (selected ranges)

- Fast fabrication and installation

- Cost‑effective compared to solid aluminium

- Custom cut‑to‑size service

Technical Specs

- Construction: Pre‑finished aluminium skins bonded to a PE (signage grade) or mineral FR core

- Nominal thicknesses: 3, 4mm

- Approx. weight (kg/m²): 3 mm ≈ 3.5; 4 mm ≈ 5.6; 6 mm ≈ 7.6

- Finishes: Matt, gloss, white, black, colours, brushed metallic, specialty

- Face film: Protective film on the display face (both faces on selected finishes)

- Machining: Panel saw, CNC router, V‑groove folding; drilling and countersinking

- Adhesion/mounting: High‑bond tapes, neutral‑cure silicones, structural adhesives, rivets/screws with oversize holes and washers

- Service temp (typical): −50 °C to +80 °C (check specific brand datasheet)

- Graphics: Accepts digital print, sign vinyl and paint (test first)

- Not recommended: Laser cutting (aluminium skins), high‑rise façade replacement without proper certification and approvals

Applications

- Retail and shop signage (interior/exterior)

- Hoardings, wayfinding and directional signs

- Exhibition and display panels

- Reception backdrops and feature panels

- Light architectural cladding and fascias (non‑façade)

- Vehicle sign blanks and mounting panels

7) Fabrication & Handling Notes

- Cut with sharp carbide saw blades; CNC route with appropriate feed/speed

- For folding, V‑groove from the back skin; leave ~0.3 mm skin for the hinge

- Remove protective film shortly after install; avoid prolonged UV exposure to the film

- Allow for thermal movement; use oversize holes and floating fixings

- Clean with mild detergent and soft cloth; avoid strong solvents/abrasives

Aluminium Composite Material (ACM) – Frequently Asked Questions (FAQs)

1. What are the common applications of ACM panels?

ACM panels are highly versatile and used in a variety of industries, including:

External cladding for commercial and residential buildings

Signage and display boards for indoor and outdoor advertising

Interior wall partitions and decorative panels

Ceiling panels and column covers

Exhibition stands and retail displays

2. Can ACM panels be used both indoors and outdoors?

Yes, ACM panels are suitable for both indoor and outdoor applications due to their:

Weather resistance: Withstand UV exposure, rain, wind, and temperature changes

Corrosion resistance: Aluminium layers protect against rust and environmental damage

Durability: Maintain structural integrity in harsh conditions

3. What finishes and colours are available for ACM panels?

ACM panels offer a wide range of finishes to suit different design needs, including:

Solid colours: Matte, gloss, or satin finishes

Metallic finishes: Brushed aluminium, silver, gold, and copper effects

Textured surfaces: Wood grain, marble, and stone imitations

Custom finishes: PVDF or polyester coatings in almost any colour or pattern

4. How durable are ACM panels?

ACM panels are exceptionally durable due to their composite structure:

High impact resistance: Strong enough to withstand external forces

UV and corrosion resistance: Ideal for long-term outdoor use

Rigid yet lightweight: Maintains shape without warping, even in large installations

5. Are ACM panels easy to fabricate and install?

Yes, ACM panels are designed for easy handling and fabrication:

Can be cut, drilled, routed, and bent using standard tools

Lightweight: Reduces installation time and labor costs

Flexible: Suitable for both flat and curved surfaces

6. Are ACM panels fire-resistant?

Standard ACM panels with a polyethylene (PE) core are not fire-rated. However:

Fire-retardant (FR) versions with a mineral-filled core are available

Compliance with local fire safety regulations should be checked for building applications

7. How do I clean and maintain ACM panels?

ACM panels are low-maintenance and easy to clean:

Use a soft cloth with mild soap and water for regular cleaning

Avoid abrasive cleaners, strong solvents, or harsh chemicals

Periodic inspection helps maintain appearance and longevity

8. Is ACM eco-friendly and recyclable?

Yes, ACM panels are recyclable:

The aluminium layers can be separated and recycled

The polyethylene core can also be repurposed in some recycling facilities

This makes ACM a sustainable choice for eco-conscious projects

Reviews

There are no reviews yet.